Contact Us

E-mail:

15315169960@qq.com

Phone:

0086-18305352588

Address:

No. 59-50, Shuguang West Road, Fushan District, Yantai City, Shandong Province

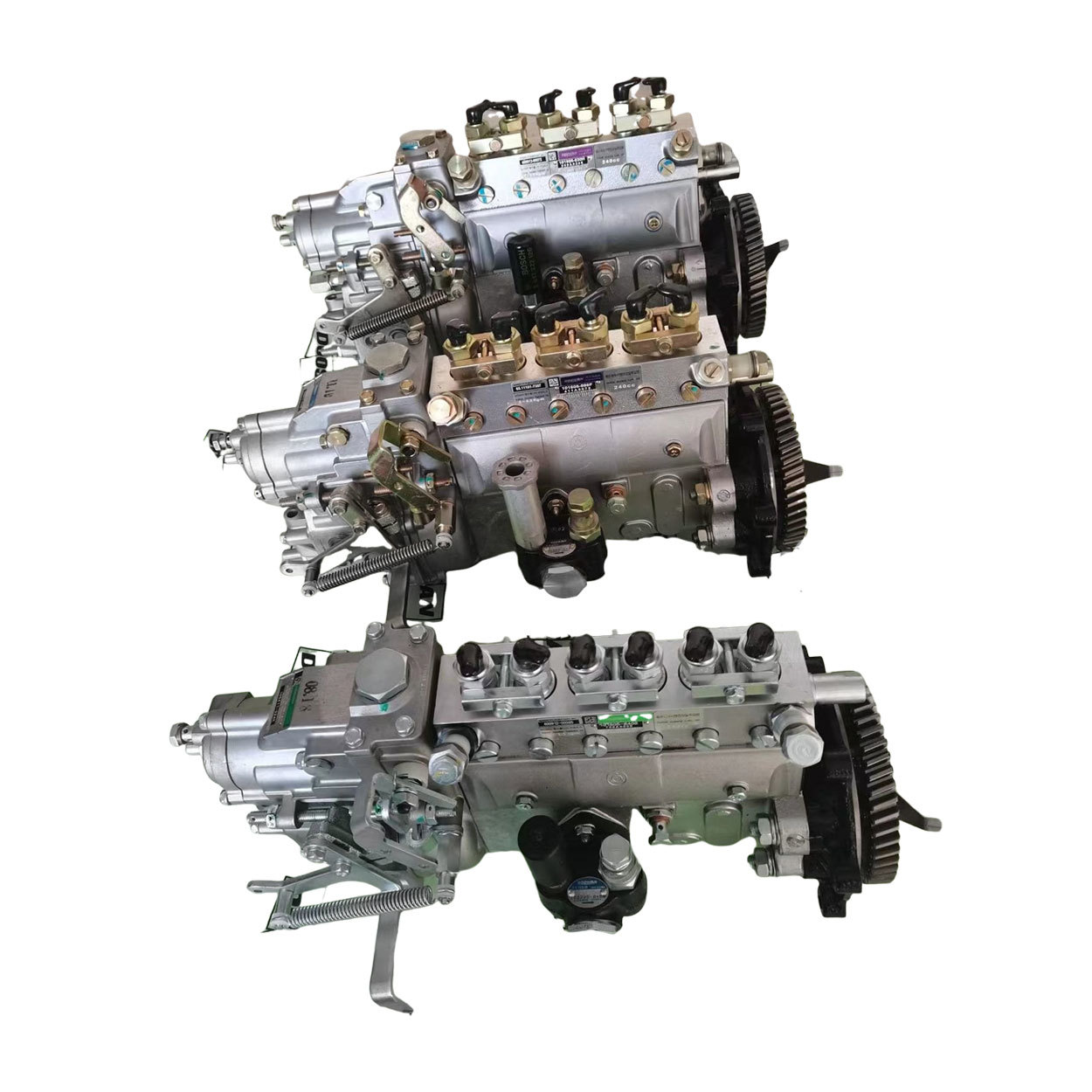

Oil pump

- Details

-

An oil pump is a crucial component in various types of machinery and vehicles, responsible for pumping oil through the system to ensure proper lubrication and maintenance of the equipment. In this article, we will explore the functions, types, and importance of oil pumps in different applications.

Function of an Oil Pump

The primary function of an oil pump is to circulate oil throughout the engine or machinery to lubricate moving parts and reduce friction. By creating a pressurized flow of oil, the pump ensures that all critical components are adequately lubricated to prevent wear and tear. Additionally, the oil pump helps to dissipate heat generated during operation and removes impurities or debris from the system, thus promoting the overall health and longevity of the equipment.

Types of Oil Pumps

There are several types of oil pumps used in different applications, each designed to meet specific requirements and operating conditions. The most common types of oil pumps include gear pumps, vane pumps, and centrifugal pumps.

Gear pumps are the most straightforward type of oil pump, consisting of two gears that mesh together to create a suction and discharge action. These pumps are commonly used in automotive engines and hydraulic systems due to their simplicity and durability.

Vane pumps, on the other hand, use a series of vanes that slide in and out of slots to create a vacuum and discharge oil. These pumps are known for their smooth and quiet operation, making them ideal for applications where noise is a concern.

Centrifugal pumps operate by using a rotating impeller to create centrifugal force, which forces oil to the pump's outlet. While centrifugal pumps are less common in automotive applications, they are commonly used in industrial settings where high flow rates are required.

Importance of Oil Pumps

Oil pumps play a critical role in the proper functioning of engines and machinery by ensuring that all moving parts are adequately lubricated. Without proper lubrication, friction between components can cause excessive wear and lead to premature failure of the equipment. By continuously circulating oil through the system, oil pumps help to maintain optimal performance and efficiency, ultimately extending the lifespan of the machinery.

In addition to lubrication, oil pumps also help to cool the engine by carrying away heat generated during operation. By removing heat from critical components, the pump prevents overheating and ensures that the engine operates within a safe temperature range. This cooling effect is essential for preventing thermal breakdown of the oil and maintaining the overall health of the system.

Overall, oil pumps are a vital component in various types of machinery and vehicles, playing a crucial role in lubrication, cooling, and maintenance. By understanding the functions, types, and importance of oil pumps, individuals can appreciate the critical role these devices play in ensuring the smooth and efficient operation of engines and equipment.

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products